Our axial and/or centrifugal fans for multiple applications are subject to building regulations. Consultation available by following the links below:

⇒ STANDARDS – RULES – CONVENTIONS

Some practical advice from installation examples and mistakes to avoid:

|

EXAMPLES |

|

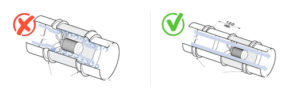

| Safety guard:

The fan may or may not be connected depending on the installation network. Always use a safety guard to avoid intrusions. |

|

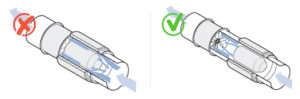

| Inlet or outlet obstructions:

Leave a minimum distance of 1x the diameter of the fan to avoid affecting its operation. |

|

| Inlet and outlet bend:

The connection from a duct to the inlet must be straight. A bend connected directly to the inlet or outlet will affect the fan’s performance. |

|

| Connection of the flexible flanges:

It is recommended that a rigid flange is inserted upstream and downstream of the fan before the flexible flanges are connected to avoid turbulence on the periphery. |

|

| Diffuser cone:

Fans not connected to the outlet may be fitted with a diffuser cone to convert dynamic losses into static regain thanks to gradual diffusion of the air speeds. |

|

| Air stagnation zone:

Air stagnation zones are to be avoided to improve scavenging. In some cases, carry out a fluid simulation study to optimize its installation. |

|

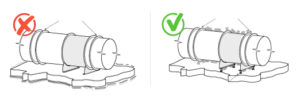

| Bulb silencer:

Leave a space between the fan and the silencer to improve air circulation and avoid turbulence that would reduce performance. |

|

| Wave propagation:

Do not attach the fan directly to the vibration-sensitive structure or platform. Use anti-vibration mounts and flexible flanges to isolate the unit and avoid wave propagation. |

|

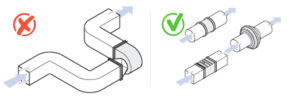

| Radial suction and discharge:

In a linear network, this type of fan must be avoided. It is preferable to opt for an in-line fan or plenum box to optimize the circuit. |

|

| Transition parts:

The use of round-square symmetrical transition parts is preferred. Asymmetric parts degrade the fan’s suction or discharge conditions. |

|